1. Introduction

For some important equipment such as substation high-voltage switch cabinets and outdoor knife switches, after long-term operation, the switch contacts and busbar connections will often heat up due to aging and excessive contact resistance. If the temperature of these heating locations cannot be monitored in advance, it is easy to cause safety accidents. We know that the temperature of the joints of high-voltage equipment is difficult to monitor, mainly because there is high voltage exposure in this area. The general temperature measurement method cannot be used because it cannot solve the high-voltage insulation problem. The wireless temperature monitoring device transmits signals through radio waves. The sensor is mainly installed on the high-voltage equipment and has no electrical connection with the receiving equipment. Therefore, the wireless temperature measurement system can fundamentally solve the problem of difficult temperature monitoring of heating parts of high-voltage equipment.

2. Causes of bus failure in medium and low voltage systems

Arc discharge combustion indicates that there is a fault in the medium and low voltage busbar. The energy released by the medium and low voltage busbar is extremely large. The arc generated when it fails will cause the pressure and temperature to rise instantly. After the arc is formed, the air in contact with it will be immediately ionized, and then it will produce explosive pressure and high temperature with extremely high energy. When these huge energies are generated, if they are not removed in time, they will cause varying degrees of damage to equipment and personnel. However, there are many reasons for this type of fault in the medium and low voltage switchgear.

2.1Equipment quality is not up to standard

The structure of the switch cabinet is not designed scientifically and reasonably. The switch cabinet is too large or too small. In addition, the manufacturing quality is not in place. When it is officially put into use, it will cause the insulation to age and the mechanical equipment to be worn, which will cause its insulation level to decrease. In terms of equipment quality, a good foundation needs to be laid for subsequent use. If the quality is not up to standard, it will lead to subsequent problems.

2.2Inadequate operation and maintenance

Operation and maintenance are also extremely important. The environment in which it is used is related to the stability and safety of the system. If it is operated in harsh environments such as high temperature, humidity, and chemical erosion, the insulation materials used will be easily damaged, which will shorten its service life. On the surface of the insulation, there will be some degree of damage, and the insulation will fail, which will lead to short circuit failures in the medium and low voltage busbar system.

2.3 Improper maintenance operation

The maintenance of power plants plays a key role in the entire system, but some people do not pay much attention to this work, and often cause faults due to improper operation. For example, during maintenance, they mistakenly leave their tools in the switch cabinet, forget to measure and record the voltage in their work area, etc. These typical improper operations will cause faults in the busbars of the medium and low voltage systems, leading to greater problems.

2.4 Others

In addition to the above factors, there are also some faults caused by the staff's carelessness, such as the switch cabinet is not sealed well, some small animals will sneak in and bite the insulation, which will cause the busbar of the medium and low voltage system to fail. In addition, with the rapid development of the power system, the structure of the power grid is always changing, and the increase in electricity consumption has led to an increase in cables and power overload, which is also where the fault occurs.

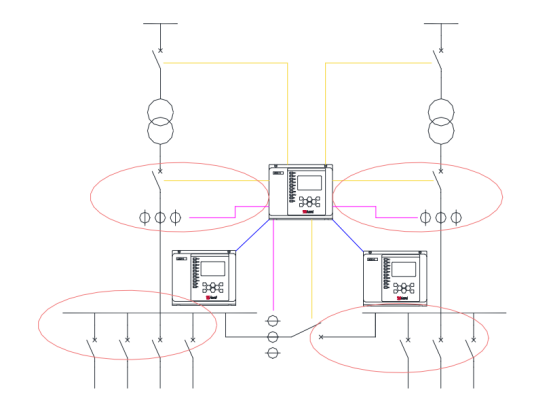

3. ARB5 arc protection device

The danger of arc-induced circuit breaker is extremely great. Arc will explode in the switch cabinet, and the burning gas and heat will quickly spread to the surroundings, and it can also melt and evaporate metals. Due to these hazards, we need a protection system. Not only that, any equipment needs protection, and the busbars of medium and low voltage systems are no exception. The protection system of the arc busbar is a system developed by many experts based on the characteristics of the busbars of medium and low voltage systems. It has many advantages. It is suitable for various operating modes and can be protected without manual switching in various operating modes. This is a convenient system that not only plays a good protective role, but also improves reliability. It is an ideal solution for protecting the busbars of medium and low voltage systems.

Power (AC, DC) | AC voltage | DC voltage | Frequency |

220V, 110V | 220V (phase voltage), 380V (line voltage) | 5A | 50/60Hz |

Circuit | AC Current Circuit | AC Voltage Circuit | Power Circuit |

Power consumption | <0.5VA/phase (rated 1A) <1VA/phase (rated 5A) | <0.5VA/phase (rated 1A) | Normal < 15W Trip < 20W |

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português tiếng việt

tiếng việt Türkçe

Türkçe العربية

العربية