1. Overview

Acrel's enterprise energy management and control platform adopts automation, information technology and centralized management mode, and implements centralized and flat dynamic monitoring and data management for the production, transmission and distribution and consumption of the enterprise, and monitors the enterprise's electricity, water, gas, steam and The consumption of various energy sources such as compressed air, through data analysis, mining and trend analysis, helps enterprises to target various energy needs and energy consumption, energy quality, product energy consumption, energy consumption of each process, process, workshop, production line Energy consumption statistics, year-on-year comparison analysis, energy cost analysis, and carbon emission analysis are carried out to provide basic data for enterprises to strengthen energy management, improve energy utilization efficiency, tap energy-saving potential, and energy-saving assessment and support.

2. Application

Steel, petrochemical, metallurgy, non-ferrous metals, mining, medicine, cement, coal, paper, chemical, logistics, food, water plants, power plants, heating stations, rail transit, aviation industry, timber, industrial parks, hospitals, schools, hotels, office buildings and discrete manufacturing industries such as automobile manufacturing, mechanical and electrical equipment, electrical products, and tool manufacturing.

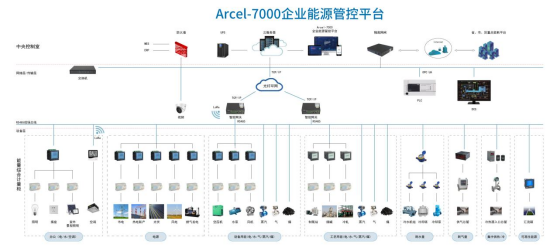

3. System Structure

The site communicates with the platform through the factory local area network, and the platform is built on the server configured by the customer. After the construction is completed, customers can log in to the web page and mobile APP with an authorized account to check the operation of each place in any place that can be connected to the local area network.

The system can be divided into three layers: the field device layer, the network communication layer and the platform management layer.

Field equipment layer: It is mainly connected to various types of instruments used in the network for the acquisition and measurement of water, electricity, gas and other parameters, and is also a necessary basic element for constructing the power distribution, water consumption, and gas consumption system. With the heavy responsibility of collecting data, these devices can be the company's various series of power meters with communication network, temperature and humidity controllers, switching value monitoring modules, as well as water meters, gas meters, and heat and cold meters from qualified suppliers.

Network communication layer: including on-site intelligent gateways, network switches and other equipment. The intelligent gateway actively collects the data of the field device layer equipment, and can perform protocol conversion, data storage, and upload the data to the established database server through the network. The intelligent gateway can store the data locally when the network fails. Continue uploading data from the interrupted position to ensure that server-side data is not lost.

Platform management layer: including application server, WEB server and data server, general application server and WEB server can be configured in one.

The platform is designed with a layered and distributed structure. The detailed topology is as follows:

4. System function

The platform adopts automation, information technology and centralized management mode, and implements centralized and flat dynamic monitoring and data management for the production, transmission and distribution and consumption links of enterprises. Real-time monitoring of the consumption of various types of energy in enterprises, through data analysis, mining and trend analysis, to help enterprises strengthen energy management, improve energy utilization efficiency and energy saving potential, and provide data basis for energy-saving transformation.

4.1 Platform login

Open the cloud platform link in the browser, enter the account name and authority password, and log in to prevent unauthorized personnel from browsing the relevant information.

4.2 Large screen display

After the user logs in successfully, they will enter the large-screen display page to display the energy consumption mark, output value, anomaly, ranking, proportion, and communication status of the enterprise and each region.

4.3 Home

The homepage displays enterprise-level statistics such as peak-to-valley electricity consumption, transformer status, annual energy consumption trends, unit consumption trends, and classified energy consumption.

4.4 Data Monitoring

Real-time monitoring of energy usage and alarms at various points of the enterprise. So that enterprise users can monitor the operation of each point in real time, and at the same time can grasp the alarm of the point faster, and provide data support for technical transformation measures such as peak cutting and valley filling, load adjustment and so on.

Real-time monitoring of energy: Real-time monitoring of energy consumption such as water, electricity, and gas to ensure the continuous and stable operation of energy consumption links, and to display functions such as power distribution diagrams, energy flow diagrams, energy balance network diagrams, and energy metering network diagrams.

Energy flow diagram: It is necessary to display the consumption of water, electricity and gas in real time on the energy flow diagram; when the energy parameter exceeds the limit and alarm, it can provide alarm importance classification, and support APP push, mobile phone SMS, email, pin Nail, voice broadcast, system pop-up window alarm prompt, etc.;

Power distribution diagram: Draw the real situation of the power distribution room into the power distribution diagram, and display the real-time parameters of the access control, flooding, electricity, water, gas and other instruments, access control flooding status and energy consumption data in real time.

Real-time statistics: real-time statistics of energy consumption values of factories, workshops, processes, and equipment in the current year, quarter, month, week, day, and shift;

Data display: Display different energy consumption parameters of different areas and different equipment through real-time curves and historical curves;

Detection: Centralized display of energy alarm information, related processing operations can be performed on alarm threshold information, and alarm parameters can be set online. When energy parameters exceed the limit, an alarm can be provided, and alarm importance classification can be provided, with APP push, mobile phone SMS , email, DingTalk, voice broadcast, system pop-up window and other alarm prompts;

4.5 Video Surveillance

Access the camera to control the actual situation in the enterprise in real time.

4.6 Transformer Monitoring

Show the load of each voltage device, so as to make scientific and reasonable planning for the transformer configuration. Through the comparative analysis of the power consumption efficiency under various operating parameters, a better operating mode is found. The load is adjusted according to the operation mode, thereby reducing the unit consumption of electricity and reducing the power loss.

4.7 Real-time monitoring of instruments

Display the real-time parameter changes of each water and electricity instrument in the form of a graph.

4.8 Energy central control

All energy-related energy parameters are concentrated in one dashboard, which can be compared and analyzed from multiple dimensions to realize the comparison of various industrial lines, and help leaders control the energy consumption, energy cost, standard coal emission, etc. of the entire factory.

4.9 Energy usage statistics

From the dimensions of energy use type, monitoring area, workshop, production process, process, work section time, equipment, team, sub-item and other dimensions, the use of curves, pie charts, histograms, cumulative charts, digital tables and other methods to calculate the energy consumption of enterprises, year-on-year , chain analysis, performance analysis, standard comparison, energy consumption per unit product, energy consumption per unit output value statistics, find out loopholes and unreasonable places in the process of energy use, so as to adjust the energy distribution strategy and reduce waste in the process of energy use.

4.10 Cost Analysis

Statistics of various energy consumption costs of each monitoring node (factory, workshop) in the current year, quarter, month, week and day, including electricity including peak electricity, peak electricity, valley electricity, valley electricity, average electricity and average electricity.

4.11 Statistics of Product Unit Consumption

Connecting with the enterprise MES system, through the product output and the energy consumption data collected by the system, the product unit consumption trend graph is generated in the product unit consumption, and the year-on-year and month-on-month analysis is carried out. At the same time, the unit consumption of the product is benchmarked with the industry/national/international advanced indicators, so that the enterprise can adjust the production process according to the unit consumption of the product, thereby reducing energy consumption.

4.12 Performance Analysis

Perform daily, weekly, monthly, annual, and specified performance statistics on the use, consumption, and conversion of various types of energy by teams, regions, workshops, production lines, sections, and equipment. Perform KPI comparison assessments based on performance indicators formulated in energy plans or quotas , to help companies understand the internal energy efficiency level and energy saving potential, and assess whether the energy consumption is reasonable.

4.13 Operation Monitoring

The system collects data on energy consumption of areas, workshops, and equipment, monitors equipment and process operating status, such as temperature, humidity, flow, pressure, speed, etc., and supports one-time operation monitoring of power transformation and distribution systems. You can quickly browse the managed energy consumption data directly from the dynamic monitoring floor plan, and support querying related energy consumption by energy type, workshop, work section, time and other dimensions.

4.14 Custom Energy Consumption Report

Users can flexibly produce various reports by customizing report headers and columns, view the energy consumption, unit consumption, cost, comprehensive energy consumption and other information of each node of the enterprise, and report year-on-year and month-on-month reports, and support exporting reports.

4.15 YoY, MoM

Provides graphical comparative analysis of energy consumption costs, including year-on-year and chain-by-period analysis by time period (day, month, year), and statistical graph comparison analysis by classification, time period, and item (location, institution, equipment) (bar chart, pie chart, stacked charts, etc.).

4.16 Analysis report

Carry out careful statistical analysis of the company's energy utilization, line loss, equipment operation, and operation and maintenance by year, month, and day, so that users can better understand the operation of the system, and provide users with a data basis to facilitate users to discover equipment abnormality, so as to identify improvement points and tap energy saving potential for energy consumption.

4.17 Energy consumption of energy-consuming equipment

Monitor the operation, shutdown and abnormal status of energy-consuming equipment, and timely solve equipment failures and shutdowns that cause normal production.

4.18 Line loss analysis

According to the node and energy classification, query the energy consumption data on the line of each node, find out the waste of energy in the process of use, such as leakage and abnormal energy consumption, and remind users to intervene in time.

4.19 Carbon Emission Management

Statistics on the change trend of total carbon emissions by region are carried out, and year-on-year analysis is carried out. Calculate the carbon emissions per unit of output value, and combine the emission reduction indicators to achieve early warning of exceeding the standard, improve the regional emission reduction level, and promote the realization of the carbon peak target.

4.20 Power Quality Monitoring

Real-time monitoring of harmonic content, three-phase unbalance, power factor, etc., to ensure that the power factor is not lower than the assessment index of the power supply bureau, to avoid fines and equipment failures.

4.21 Operation and maintenance management

The system supports equipment operation and maintenance management such as daily equipment inspection plans, dispatching workers, eliminating shortages, applying for repairs, dispatching workers, etc., which is convenient for operation managers to formulate inspection plans, dispatch workers, and inspectors to perform inspections, complete work orders, and inspections Find problems and eliminate deficiencies, report faults for repairs, follow up maintenance progress, and meet the needs of daily inspections and equipment maintenance.

4.22 Alarm Management

Aiming at the normal development of electricity, the dual control of power limitation and energy consumption, it can realize the alarm of abnormal electrical parameters, the alarm of electrical fire hazards, the alarm of energy consumption exceeding the standard, the alarm of power limitation, etc., to help enterprises give early warning and avoid fire accidents and energy consumption caused by fines. Cost is too high. Supports hierarchical and classified alarms, and can distribute and close-loop alarms.

4.23 Energy consumption meter reading

The meter reading value and difference value of the meter reading instrument in the time period can be customized, and the classification and sub-item of the meter reading can be customized.

4.24 Energy consumption analysis custom time meter reading

The energy consumption value of each topology node in the time period can be customized, and the classification and sub-item of the energy consumption value of meter reading can be customized.

4.25 Capacity Demand Report

Provide capacity demand report, real-time display of capacity demand price changes, help enterprises realize capacity change and reduce basic electricity bills.

4.26 Multi-rate report

Statistical analysis of peak, peak, flat, and valley electricity consumption and costs, providing data support for enterprises to use electricity by time and optimize cost-effectiveness.

4.27 Document Management

Documents such as national standards, energy management systems, and energy index systems can be archived, and related documents can be quickly inquired. System management of instrument ledger, support for uploading and downloading of files.

4.28 3D Visualization Large Screen

Virtual simulation of the scene, showing the operation and energy consumption of each area, can achieve layered preview, transition display, style switching, intelligent inspection and other effects, support the custom binding of models and monitoring points.

4.29 3D Subsystem

Perform virtual simulation of each power subsystem to display the real-time status and energy consumption of the power pipeline of the subsystem, equipment, and energy consumption, so as to realize the dynamic energy flow effect.

4.30 Industrial configuration

The configuration diagram can be customized by graphical editing to display the operating status and energy consumption of the equipment, and custom materials can be uploaded and monitoring data can be bound.

4.31 Custom Cockpit

The cockpit can be customized through a graphical operation mode, and the collected data and various statistical data can be displayed in graphs such as line charts, pie charts, and tables. The data sources include API, database query, MQTT, Excel, etc.

4.32 Basic data management

Configure, modify, delete and manage items, detectors, equipment models, electrical parameters, nodes, energy, publicity, and related parameters of the system, and manage user additions, authorization, and contracts.

4.33 Mobile APP

The APP supports Android and iOS operating systems, which is convenient for users to master enterprise energy consumption, production line comparison, efficiency analysis, year-on-month analysis, energy consumption markdown, and event records according to different dimensions such as energy classification, area, workshop, process, team, and equipment. , Operation monitoring, abnormal alarm, power distribution diagram, process flow diagram, energy flow diagram.